Specification DASS Fill & Drain Rigs – Qatar

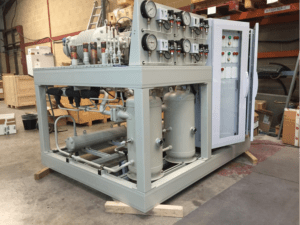

Our task was to manufacture and deliver 6 sets of 03 DASS Fill and Drain rigs for the BAE Systems export market, Qatar.

DESCRIPTION

Lightfoot were contracted to supply a multi-room refrigeration system that included significant redundancy. This would ensure continued operation in case of a breakdown where repair support would be distance based ashore. Lightfoot design was submitted to DNV by the customer for independent review and approval for use on an oil rig. This was approved as meeting all design and safety requirements without any changes required.

PROBLEM

Existing installed equipment was dated and unreliable which required spares and repair services to be helicoptered in from ashore for any breakdowns. This was costly and time consuming with a detrimental impact when refrigeration system went down. The customer therefore required robust and reliable equipment with significant redundancy within the system, allowing any repairs to be undertaken during scheduled service visits from ashore whilst maintaining refrigeration system operation.

SOLUTION

A dual evaporator was designed for each room as well as two parallel refrigeration systems that provided the 200% redundancy required and enabled a defective system to be isolated. Thus, maintaining the system operation until a repair could be affected during a scheduled service visit.

The project: –

Due to the success of the Refrigeration build and install, Lightfoot were asked to bid for a custom Air Conditioning Plant (ACP) and Air Handling Unit (AHU) design and then build.

Lightfoot were successful in their bid for the ACP and AHUs and designed and built the equipment which was also approved for use and then installed on the platform to provide air-conditioned air to the accommodation quarters on the oil platform.

Our task was to manufacture and deliver 6 sets of 03 DASS Fill and Drain rigs for the BAE Systems export market, Qatar.

Lightfoot successfully bid for the contract to design and build a multi-room refrigeration plant for the Brazilian Navy flag ship aircraft carrier SAO PAOLO.

Lightfoot were contracted to supply a multi-room refrigeration system that included significant redundancy.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |